The Crude Unit being the only one processing the entire amount of feed in the Refinery, requires special attention with regards to reliability.

By capital cost reasons there is a definite trend to install very large capacity furnaces, sometimes even only one for the complete Refinery, therefore there is no typical size or typology for such kind of furnaces.

Based on best compromise of operability, reliability and investment cost the selection of the crude heaters for new installation is recommended as follows:

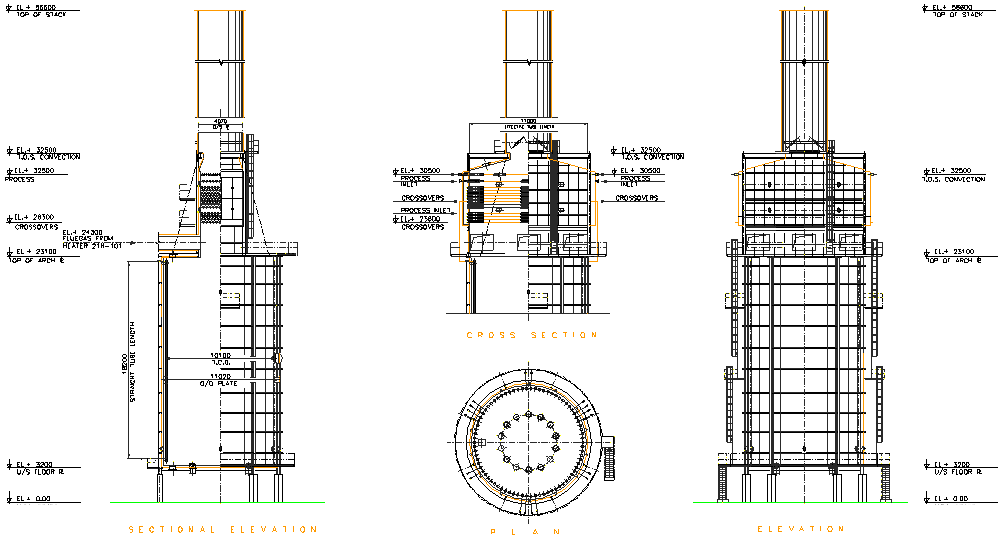

Fig.1

• Up to 40 Million kCal/hr thermal capacity the vertical cylindrical type of heaters (fig.1) is preferred. This generally allows good plot arrangement, low cost and reduced number of burners.

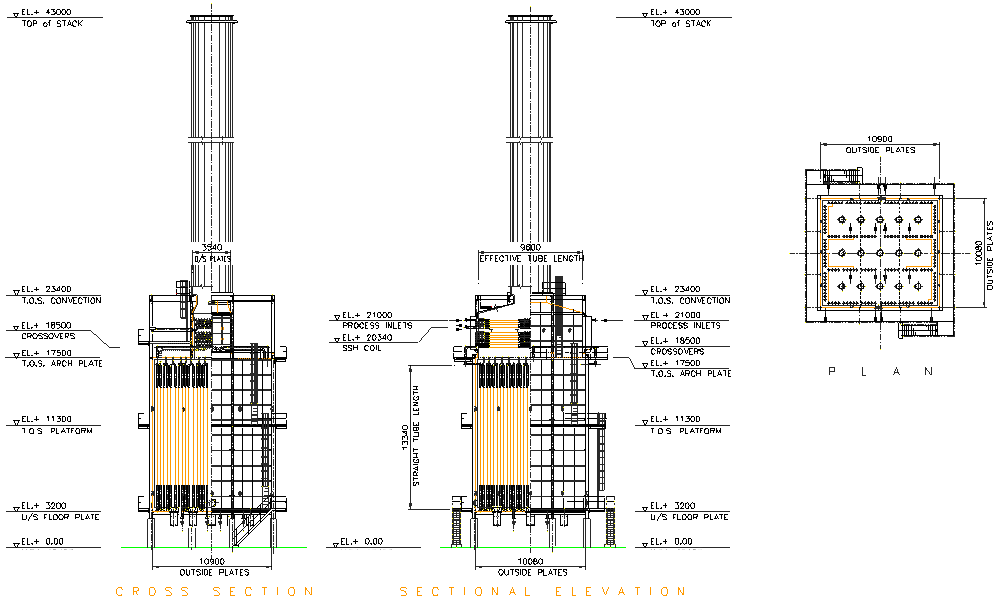

• From 40 to 150 or more Million kCal/hr thermal capacity the so called “High Intensity” type will allow most compact design and minimal number of burners at the minimum capital cost.

The “High Intensity” heaters (fig.2) feature vertical tubes in a box envelope with tubes being fired partly from one and partly from both sides. Very large capacity forced draft burners are installed in the floor of the furnace working at low excess air.

Fig.2