Selection of heaters for the Hydrocracking units is strongly impacted by two main factors:

- Relatively high process outlet temperature

- Very high process pressure (typically 200 bars)

This two constraints result in the need for very thick high alloy tubes making the coil lay out the major factor in the competitive design of the heaters.

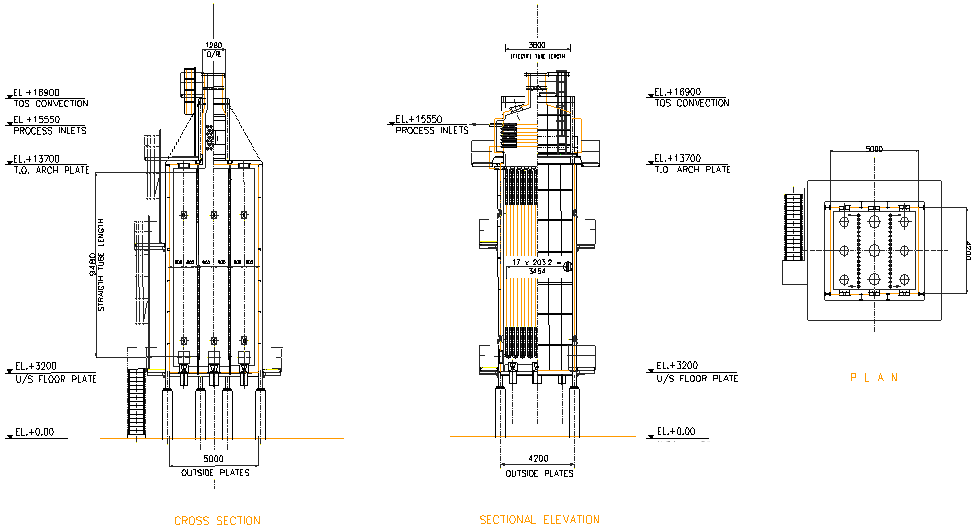

To cope with the above, state of the art technology is worldwide recognized to be the double fired tubes / vertical box heater (fig. 1) featuring stainless steel coil material (typically ASTM grade 321H or 347H).

Fig.1

The double fired arrangement, where tubes are fired from both sides at minimal heat flux misdistribution and the optimized tube diameter selection allow keeping the tube thickness of such high alloy material within the range of commercially available coil material. Since no other specific process need is limiting the design, the most economical vertical tubes arrangement is selected.