Fired heaters in Visbreaking service (as well as in any cracking application) are to be considered as reactor furnaces and their design needs all necessary knowledge of cracking kinetics in general and Visbreaking process specifically.

Based on the feed composition and the coil geometry, ICS takes the advantage of simulation programs which enables designers to predict the conversion rate and product composition at different temperature / pressure / heat flux conditions. The model will also predict the tubeskin and film temperature profiles allowing to avoid film overheating and keeping control on the formation of undesired by-products (like the asphaltenes) that may have negative impact on the stabilization of the fuel oil produced in the Visbreaking unit.

The program takes also into account both liquid phase and vapour phase reactions and contains a model for the prediction of coke build up at a given forecast of running conditions.

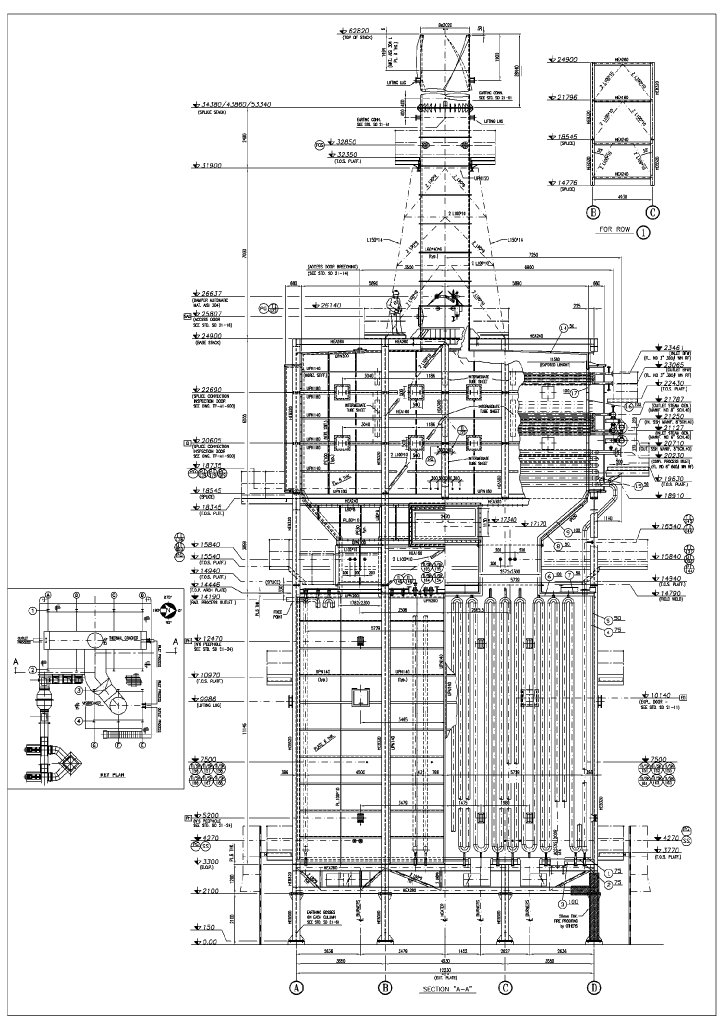

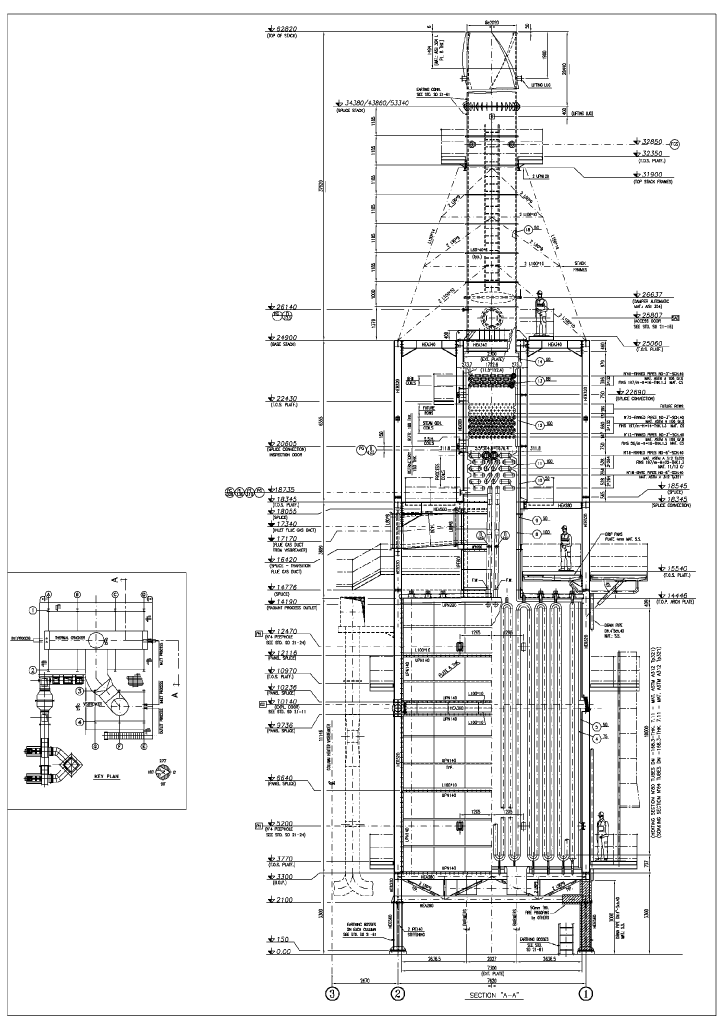

As far as heater coil geometry is concerned, the simulation program shows no particular need for any specific lay out, therefore the most economical arrangement may be preferred, like the vertical cylindrical one (fig. 1 and 2)

Fig.1

Fig.2